What Is a Hose Pipe Nipple?

A hose pipe nipple is a specialized fitting featuring a male threaded connection on one end and a barbed hose connector on the other. The barbed end may match the pipe thread size or be reduced for smaller hoses. These fittings are commonly made from 304 or 316 stainless steel, offering superior strength and corrosion resistance for demanding applications.

Key features include:

NPT (National Pipe Taper) threads for leakproof sealing

Hose barb design for secure hose attachment

ANSI B1.20.1 compliant for quality assurance

Highpressure resistance (up to 20,000 psi in some applications)

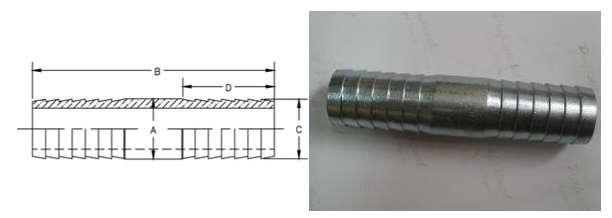

Hose Nipple Size Chart

Below is a standard size reference for hose pipe nipples:

| Pipe Size | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 |

| A | 0.675 | 0.84 | 1.075 | 1.525 | 2.162 | 2.162 | 2.505 | 3.1 | 4.06 |

| B | 3.375 | 3.375 | 3.625 | 3.625 | 3.75 | 3.75 | 5.5 | 6 | 7.75 |

| C | 0.645 | 0.845 | 1.075 | 1.405 | 1.64 | 2.095 | 2.505 | 3.1 | 4.06 |

| D | 1.281 | 1.281 | 1.281 | 1.281 | 1.281 | 1.281 | 2.25 | 2.75 | 3.5 |

Note: Custom sizes are available for specialized requirements.( from 1/8-12″)

How to Install a Hose Nipple

- Threaded Connection

Screw the NPTthreaded end into the corresponding female port using pipe tape or sealant for a secure fit.

- Hose Attachment

Slide the barbed end into a compatible rubber or thermoplastic hose.

Secure with a hose clamp or crimp ferrule for pressure retention.

- Pressure Testing

Always test the connection at 50% above working pressure before full operation.

Applications of Hose Nipples

Hose nipples are essential in industries requiring reliable fluid transfer:

Chemical Processing – Acids, solvents, fertilizers

Marine & Offshore – Saltwater cooling, bilge systems

Agriculture – Herbicide/pesticide distribution

Oil & Gas – Fuel transfer, hydraulic systems

Manufacturing – Coolant lines, compressed air

Material Selection Guide

| Material | Advantages | Best For |

| 304 | Cost-effective, good corrosion resistance |

Food processing, water systems |

| 316 | Superior chloride resistance |

Marine, chemical, offshore |

| Brass | Excellent machinability |

Low-pressure pneumatic systems |

| Carbon Steel | High strength, economical |

Industrial oil/gas applications |

Why Choose Cangzhou Hongxin for Hose Nipples?

As a leading manufacturer and supplier of stainless steel pipe fittings, Cangzhou Hongxin offers:

Full product range: Including hose nipples, threaded elbows, tees, unions, and pipe caps

Custom solutions: Special sizes, materials, and threading standards

Quality assurance: ANSIcompliant manufacturing processes

Competitive pricing: Factorydirect supply with no middleman markup

Our expertise in fluid transfer systems ensures you get durable, precisionengineered fittings for any application.

Frequently Asked Questions (FAQs)

Q1: Can hose nipples be used with hightemperature fluids?

A: Yes, 316 stainless steel nipples withstand temperatures up to 1500°F (816°C).

Q2: What’s the difference between NPT and BSP threads?

A: NPT (US standard) has a tapered thread, while BSP (British standard) may be parallel or tapered. Always match thread types.

Q3: How do I prevent hose slippage on barbed nipples?

A: Use double clamps or crimp ferrules for highpressure systems.

Q4: Are there reusable hose nipples?

A: Stainless steel nipples are durable and reusable, but hose clamps may need replacement.

Q5: Where can I buy bulk hose nipples?

A: Cangzhou Hongxin supplies wholesale quantities with custom packaging options.

Conclusion

Hose nipples are critical components for secure fluid transfer across industries. Proper size selection, material choice, and installation ensure leakfree performance under pressure.

For highquality stainless steel hose nipples, Cangzhou Hongxin provides certified, competitively priced fittings tailored to your system requirements. Contact us today for technical support or bulk quotations.